A sheet metal fabricator is a skilled tradesperson who works with thin sheets of metal to create various structures and components. Their job involves cutting, shaping, bending, and assembling metal sheets into products or parts used in construction, manufacturing, and other industries. Here are some key tasks a sheet metal fabricator typically performs:

- Measuring and Marking: They measure and mark the dimensions on metal sheets according to blueprints or design specifications.

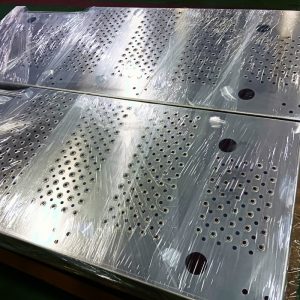

- Cutting: Fabricators use tools like shears, plasma cutters, or lasers to cut metal sheets into the required shapes and sizes.

- Bending and Shaping: Using machines like press brakes, rollers, or hammers, they bend and shape the metal into the desired form.

- Assembling: They join metal parts together using techniques like welding, riveting, or bolting to create a final product.

- Finishing: After assembly, fabricators might sand, polish, or coat the metal surfaces to enhance appearance and prevent corrosion.

- Quality Control: They inspect the finished product to ensure it meets the required standards and specifications.

Sheet metal fabricators work in various industries, including HVAC (heating, ventilation, and air conditioning), automotive, aerospace, and construction, making items like ductwork, roofing, vehicle parts, and machinery components.

A sheet metal fabricator works with thin sheets of metal to create various products and components. Their role involves shaping, cutting, and assembling metal materials to build parts for industries like construction, manufacturing, and automotive. Here’s what they typically do:

- Blueprint Reading: They read and interpret blueprints, schematics, and technical drawings to understand the specifications of the metal parts or products they need to create.

- Measuring and Cutting: They measure and mark metal sheets according to the designs, then cut the sheets using tools such as shears, saws, or laser cutters.

- Shaping and Bending: They use machines like press brakes or rollers to bend and shape metal into specific forms.

- Joining and Assembly: They assemble metal parts by welding, riveting, or fastening to create the final product or component.

- Finishing: Fabricators may finish the product by polishing, painting, or applying protective coatings to enhance durability and appearance.

- Inspection: They inspect the completed work for accuracy and quality, ensuring it meets design specifications.

Sheet metal fabricators work on a wide range of projects, including HVAC ductwork, metal roofing, car bodies, and industrial equipment. They need to be skilled with tools and machinery, have a good understanding of materials, and be able to work with precision.

From Sheet Metal Fabrication Companies in China, china sheet metal fabrication manufacturers, china sheet metal fabrication companies – JIATONG

Click sheet metal fabrication company china or china sheet metal forming manufacturers to learn more about sheet metal fabrication services.

For all your electrical enclosures from China, contact china sheet metal fabrication factory JIATONG now.